Flanges

These flanges are manufactured to specifications of ASME B16.5, ASME B16.47, ASME B16.48, BS EN 1092, BS 4504, API-605, API-590, MSS SP44, DIN 2632-2638, DIN 2576, 2642, 2527, 2566

Blind Flanges

Specifications : ANSI B 16.5 from 1/2″ to 24″ and classes150 to 2500 (complete range)

Applications : Used in quick assembly to save the cost, these are also used in less strict requirements in terms of length of pipe section.

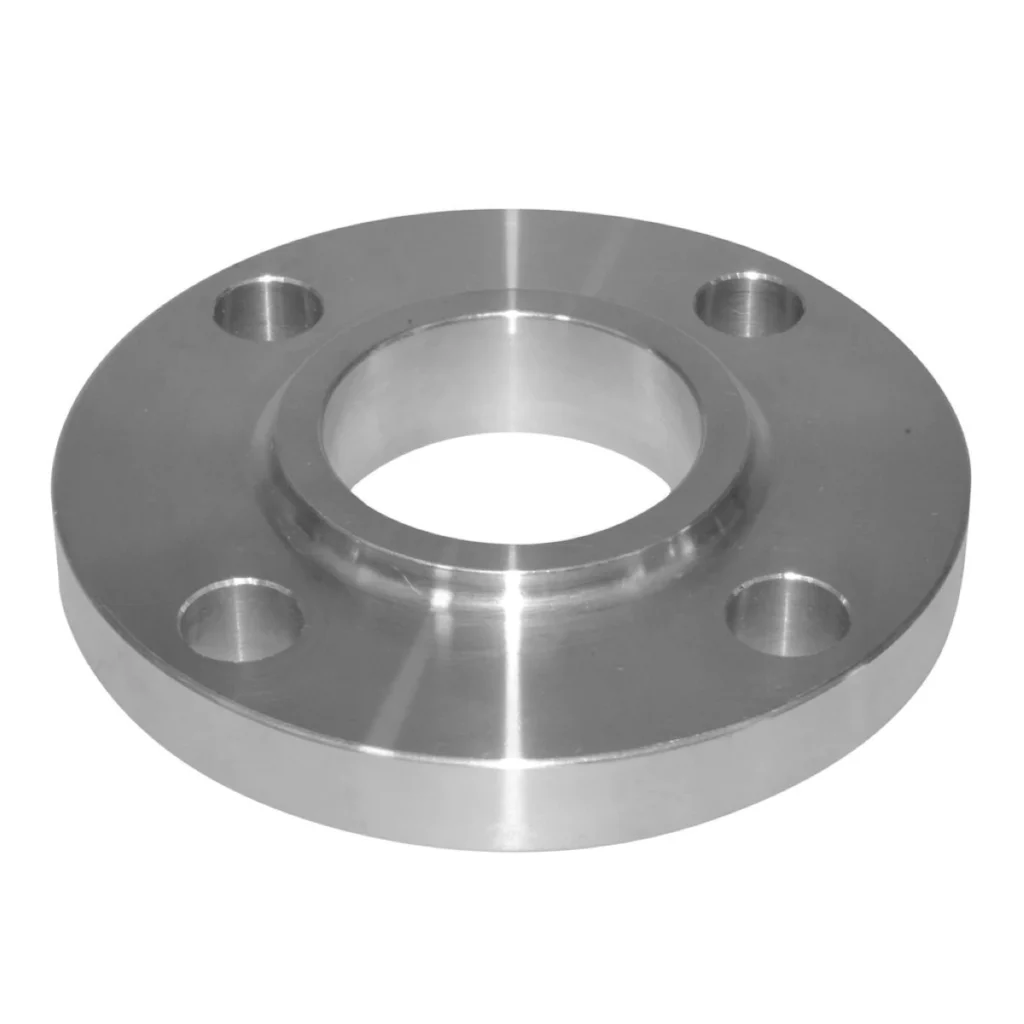

Slip on Flanges

Specifications : ANSI B 16.5 from 1/2″ to 24″ and classes150 to 2500 (complete range).

Applications : Used in quick assembly to save the cost, these are also used in less strict requirements in terms of length of pipe section.

Socket Welding Flanges

Specifications : ANSI B 16.5 from 1/2″ to 24″ and classes150 to 2500 (complete range)

Applications : Recommended for orifice flanges. These work as substitute

for slip-on-flanges in the cases where the diameter of the tube is very

small and working pressure is very high.

Lap joint Flanges

Specifications : ANSI B 16.5 from 1/2″ to 24″ and classes150 to 2500 (complete range)

Applications : Recommended for orifice flanges. These work as substitute

for slip-on-flanges in the cases where the diameter of the tube is very

small and working pressure is very high.

Threaded Flanges

Specifications : ANSI B 16.5 from 1/2″ to 24″ and classes150 to 2500 (complete range)

Applications : These flanges are used in special requirements to work under high temperature and pressure, making sure no welding joint is made at the assembly.